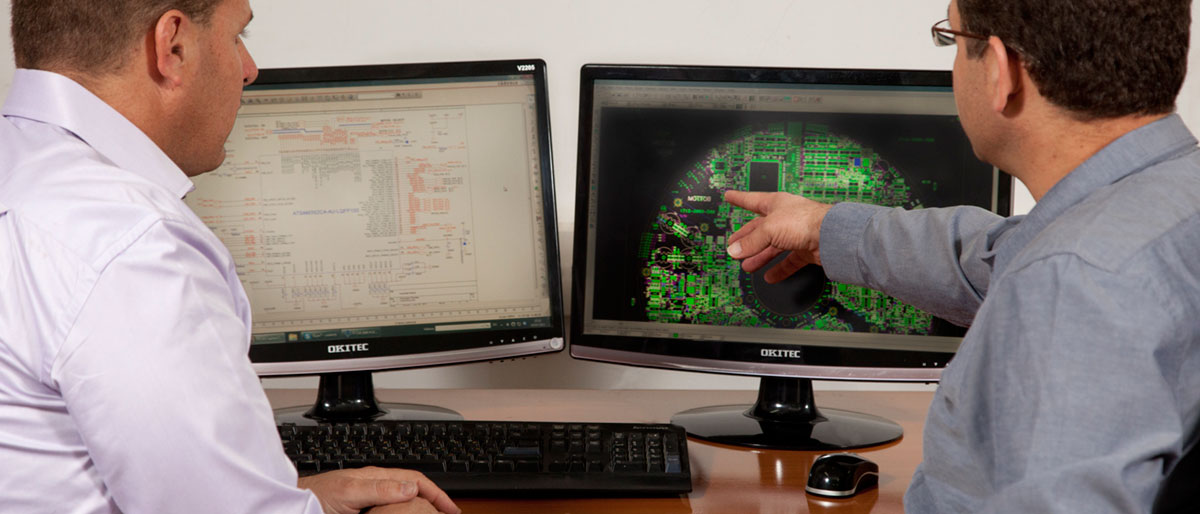

Product Development

Trinity’s engineers work with our customers to create new products. The ideas may be scratched on the back of the proverbial napkin or defined in a 100-page document. They meet with our customers to create a proposal covering all product areas. This proposal includes drawings, packaging, cabling, printed circuit boards, software, and instruction manuals. The next step is to produce a prototype for customer evaluation. The prototype may or may not be close to the production model, depending on the complexity of the product. In most cases, this will be followed by a pre-production prototype to iron out the wrinkles in the production version. Connect with us to discuss your project needs for PCB boards in Edmonton, Calgary and throughout Alberta and British Columbia.

Electronic Design

Trinity Electronics Systems Ltd has completed over 700 projects over the last 35 years. Designs range from simple (single chip water level monitor) to complex (systems for diagnosing hydroelectric power generating plants). We provide the right level of technology to solve each problem at the right price.

Trinity Electronics Systems Ltd has also successfully created products for the retrofit markets. Suppose the original manufacturer goes out of business, drops the product line, or refuses to make modifications for a customer. In that case, Trinity Electronics Systems Ltd can engineer a custom product that fits the customer’s application exactly or even provides enhanced functionality… often at a much better price. Please see the list of clients we have worked with in the past.

Printed Circuit Board Design

A printed circuit board or PCB is a board used to connect electronic components. Most of Trinity Electronics Systems Ltd’s products are based on printed circuit boards. The boards range from simple, single-sided boards with a few passive components to multi-board, multi-layer packages. The boards’ components may be surface mount, through-hole, or frequently, a combination of both component types. The general purpose of PCB boards is to connect all the components that a particular device may need with the help of different materials. It’s the most efficient and complex way to provide functionality to a device.

“I highly recommend Trinity for any board design projects.”

– Clarence Rozak, Baker Atlas Canada.

Common Uses of Printed Circuit Boards

Almost everyone uses devices that incorporate printed circuit boards without knowing it. The main applications for printed circuit boards are:

LEDs: They are preferred in both commercial and residential settings due to their energy efficiency and ability to transfer heat away from the bulb. Since high temperatures make LEDs burn out faster, aluminum PCB boards eliminate the need for an extra heat sink.

Industrial equipment: The industrial sector uses printed circuit boards made of thermal-resistant durable metals, often thicker than typical PCB boards. This material makes them durable and high-powered to handle harsh conditions.

Medical devices: PCB plays a huge role in devices used for diagnostics, treatment, monitoring, and more.

Consumer electronics: Computers, smartphones, and many other consumer products that we use daily require PCBs. These products would not exist without PCBs. As most manufacturers produce smaller smartphones, small PCBs with a high volume of connections will be in high demand.

Safety equipment: Many aspects of security systems rely on PCBs. From smoke detectors and electronic door locks to security cameras, PCB boards play an essential role in many types of security equipment. For the past 40 years, we have been engaged in numerous interesting projects. To see the kind of projects we have been part of, check out the gallery before you contact us regarding your projects.

Hazardous Location (Hazloc) Design

Trinity Electronics Systems Ltd has designed hazardous location equipment for over 30 years. Our designs include explosion-proof and intrinsically safe equipment for both Division 1 or Division 2 areas. Our designs also include communications equipment, gas well controls, cabinet heaters, pump controls, and industrial timers.

Microprocessor Software Development

The company has focused on the PIC series of microprocessors from Microchip, but other processor families are used when the job calls for them. Hundreds of projects have left the company with thousands of reusable code lines that speed up new software development. The PIC series has proven to be a wonderful choice due to its low power consumption, high speed, low cost, extended temperature range, onboard memory, and single-chip configuration.

Contract Manufacturing

Although not a contract manufacturer by strict definition, the business model that Trinity Electronics Systems Ltd seeks is to both design and manufacture products for our customers. Product volumes range from a single unit to 10,000 pieces per year. If it’s economical, products may be subcontracted to a contract manufacturer.

Trinity Electronics Systems Ltd will still monitor the manufacturing to maintain manufacturing quality.

Printed Circuit Board

At Trinity Electronics Systems Ltd, we understand the pivotal role of Printed Circuit Boards (PCBs) in modern electronic devices. PCBs serve as the backbone of electronic systems, providing a platform for seamlessly integrating electronic components. We have the expertise and resources to design and manufacture PCBs that optimize performance, reliability, and efficiency.

A Printed Circuit Board comprises a substrate material, typically made of fibreglass-reinforced epoxy, with conductive pathways etched or printed onto its surface. These pathways, known as traces, facilitate the flow of electricity between electronic components, such as resistors, capacitors, and integrated circuits. PCBs streamline the assembly process, reduce production costs, and enhance overall system functionality by eliminating the need for cumbersome wiring and soldering.

Types of Printed Circuit Boards and Their Applications

Trinity Electronics Systems Ltd offers a comprehensive range of Printed Circuit Boards (PCBs) tailored to various applications and industries.

Single-sided PCBs

Single-sided PCBs feature conductive traces on one side of the substrate for simple electronic circuits. These cost-effective boards are commonly used in consumer electronics, such as calculators, remote controls, and LED lighting.

Double-sided PCBs

Double-sided PCBs offer increased flexibility and functionality and have conductive traces on both sides of the substrate. These versatile boards accommodate complex circuit designs and are widely employed in automotive systems, industrial controls, and telecommunications equipment.

Multi-layer PCBs

Multi-layer PCBs have multiple substrate layers with interconnected conductive traces, enhancing performance and reliability. These advanced boards are indispensable in high-density electronic devices, including smartphones, tablets, and medical instruments, where space constraints and signal integrity are critical.

Flexible PCBs

Flexible PCBs are engineered from flexible polymer materials and offer exceptional bendability and adaptability to fit unconventional form factors. These rugged boards are ideal for applications requiring durability and miniaturization, such as wearable devices, automotive interiors, and aerospace systems.

At Trinity Electronics Systems Ltd, we leverage state-of-the-art technology and quality control measures to make sure that our PCBs meet the highest industry standards. Our advanced manufacturing facilities, strategically located in Saskatoon, Regina, and Edmonton, are equipped with cutting-edge equipment and staffed by skilled technicians dedicated to delivering superior products and services.

Whether you require prototype development, mass production, or custom PCB solutions, Trinity Electronics Systems Ltd is your trusted partner for all electronic design manufacturing needs.

Trinity Electronics Systems Ltd is committed to delivering innovative, reliable, cost-effective electronic solutions tailored to your requirements. Contact us today to learn more about our comprehensive range of Printed Circuit Boards (PCBs) and discover how we can help bring your electronic designs to life. You can also reach out to us for circuit design services.

PCB Boards in Edmonton, Calgary, and throughout British Columbia

We have experience handling small, complex and custom products for our customers.